Course Overview:

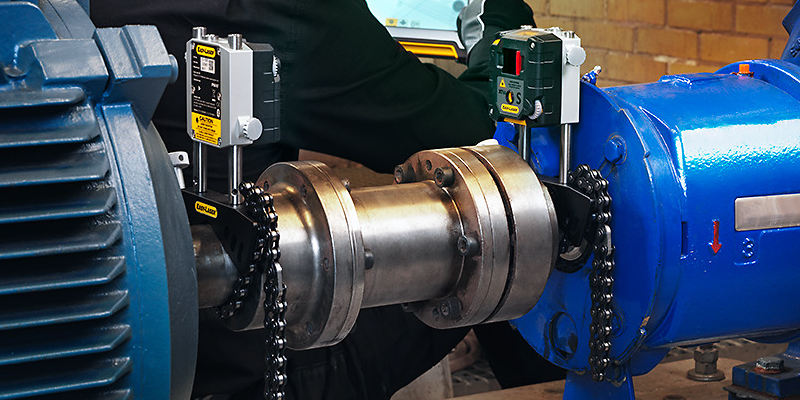

The Straightness in Rotary Axes course focuses on the concept and techniques of achieving straightness in rotary axes. It covers methods and tools used to ensure precise alignment of rotating parts, leading to improved performance, reduced wear, and increased service life.

Course Objectives:

- Understand the concepts of straightness in rotary axes and its importance in mechanical industries.

- Learn advanced techniques and methods for measuring and adjusting rotary axis straightness.

- Apply standards and correct procedures to ensure accurate alignment of rotary axes.

- Analyze common challenges and errors in rotary axis straightening and how to resolve them.

Training Content:

- Introduction to straightness and basics of rotary devices.

- Methods for measuring straightness and the tools used.

- Techniques for adjusting straightness and compensations.

- Practical applications in aligning rotary axes in mechanical industries.

Target Audience:

This course is designed for mechanical design engineers, mechanical maintenance technicians, and anyone working in industries that utilize rotary devices. It aims to equip participants with skills in rotary axis straightening to enhance performance and precision.