Main Course Modules:

1. Introduction to the Maximo System

– What is Maximo and its role in operations and maintenance management

– Benefits of using the system to improve operational processes

– Familiarization with the user interface and basic navigation

2. Operational Equipment Management

– Registering and classifying equipment and assets

– Linking equipment to locations and operational systems

– Updating equipment data and maintenance history

3. Fault Report and Work Order Management

– Receiving and logging fault reports

– Converting fault reports into work orders

– Tracking, executing, and closing work orders

4. Preventive Maintenance and Planning

– Creating preventive maintenance plans and schedules

– Scheduling routine maintenance activities

– Utilizing predefined job plans (Job Plans)

5. Resource and Materials Management

– Planning and assigning maintenance teams

– Requesting and issuing materials and spare parts

– Managing essential operational inventory

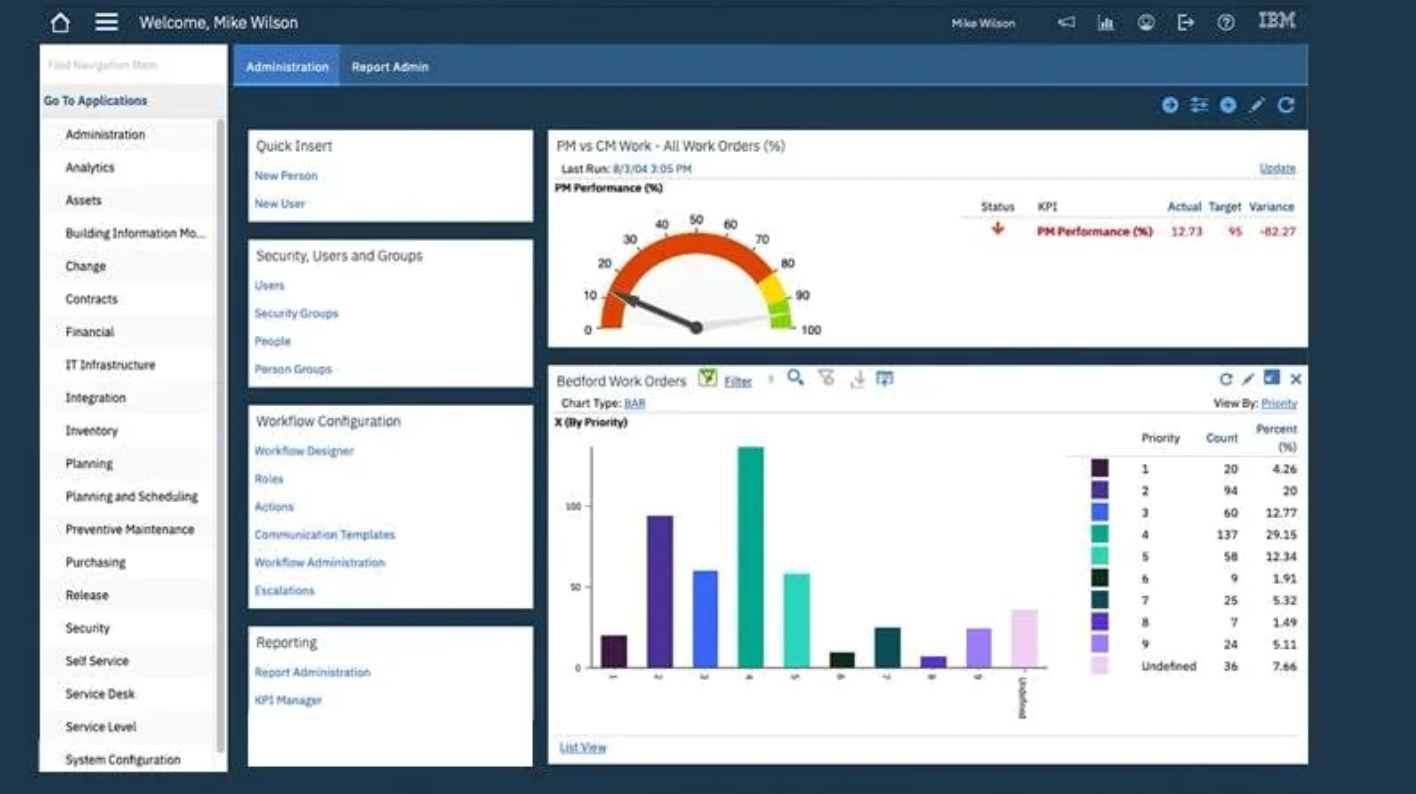

6. Reporting and Monitoring

– Generating work order and equipment reports

– Key performance indicators (KPIs) for operations and maintenance

– Tracking maintenance costs and completion progress